RAW MATERIALS The main Raw materials used in brewing KAUKO beers; Inkera and INGINGO are; Bananas, Sorghum, Ginger and Tea. Specifically, Inkera is extracted from sorghum, bananas, whereas INGINGO is extracted from bananas, Ginger, Tea and Sugar.

KAUKO stocks, on average, between 100-125 tonnes of bananas, three (3) tonnes of sorghum, 2.5 tonnes of ginger and 500kgs of Tea a month for the entire brewing process. This translates into a average of 4,000Litres of brewed beer, or 500crates a day. Currently, the limitations of space and the facility capacity render KAUKO to operate for 25 days in a month, leaving the rest of the days for; training, cleaning and calibration of machines.

KAUKO awards supply contracts to farmer cooperatives to supply sorghum, bananas and ginger. Farmers are looking up to the expansion plans of KAUKO to increase their production capacities to match the raw materials demand by the Burera-based brewery

“Our specialty is farming….mostly grains like Sorghum and maize. We have good business partners like KAUKO buying from us sorghum at a fair price.

KAUKO gave us a supply quota of at least 2 tonnes per month and we try to meet this supply requirement…although last month we supplied them 4 tonnes. They always pay on time.

They (KAUKO) have informed us of their expansion plans, and we are also preparing farmers for this development. We plan to double our production capacity as well , so we can increase our incomes to reach our goals as COPACI and as individuals

Many of our members in the cooperative have managed to educate their children, for instance, three of our members have children who have reached university, even others have learners in lower classes.

Members also engage in so many other small businesses, because they want to live a good life as modern Rwandans.

We also have some young unmarried women and men, we support them. Even us who are married, we engage in business activities for personal development. We hope that KAUKO expands soon and increase production capacity, we shall achieve a lot more”

ANACOITE NYINARIGABA, PRESIDENT OF THE COPACI (COOPERATIVE) ABUNZE UBUMWE | GACYORO VILLAGE, GAFUMBA CELL, RUGARAMA SECTOR, BURERA DISTRICT

Raw bananas are stored in a special cool dry room installed with pallets, under special from microbes.

Bananas are stored in this room for about 3days under moderated temperature called “Guhungiriza” in Kinyarwanda, before they ripen. Usually, moderate heat is generated from the burning charcoal under the pallets to ripen the bananas.

Electric machine is used to press the banana juice (Umutobe) through the process called DECANTATION…which results in refined juice. Two (2) big locally made boilers, each carrying 500litres of banana juice are fired up under very hot furnace at boiling point.

Currently, KAUKO boils about 4,000litres of banana juice on average a day.

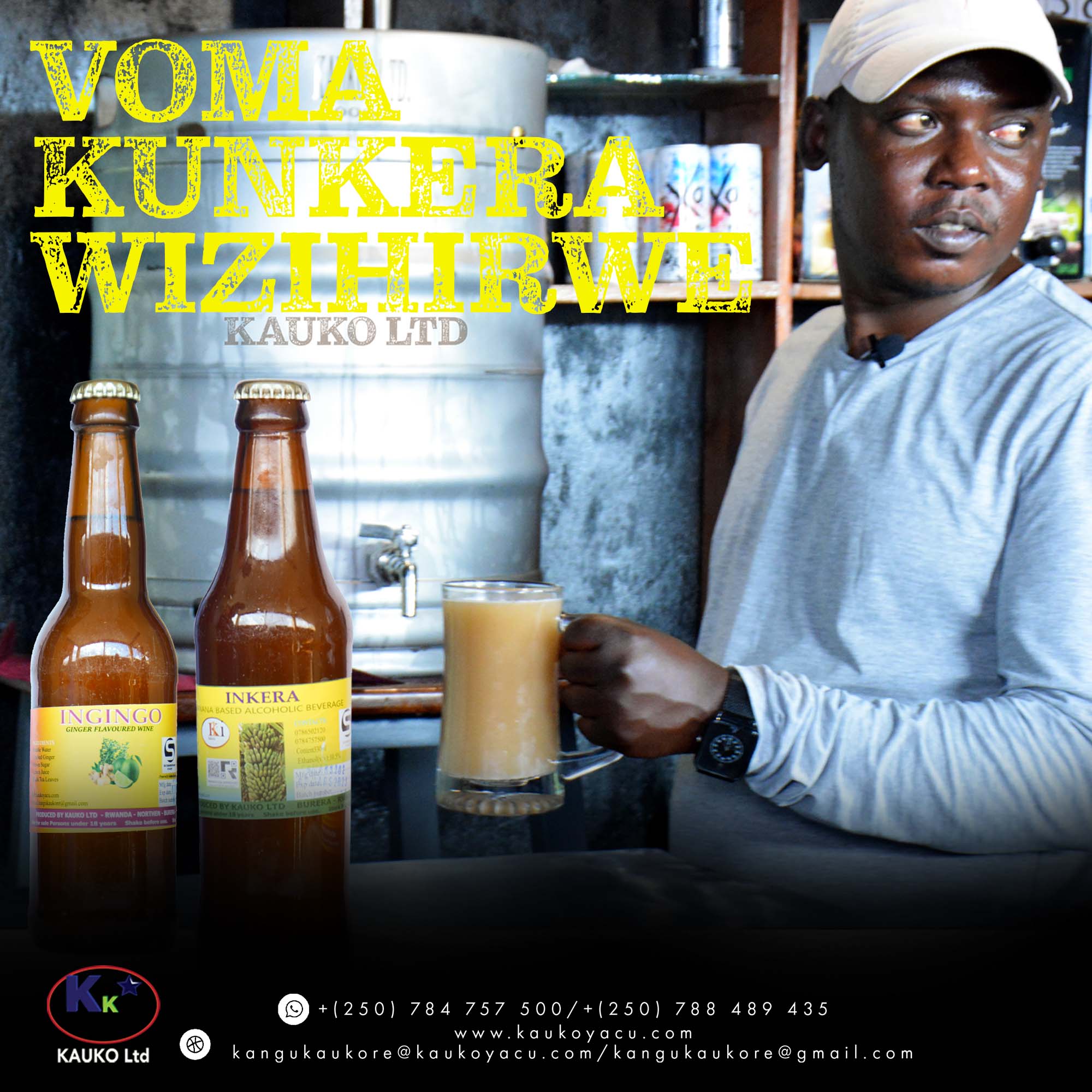

From here, through the pipe system, the boiled banana juice is pumped directly to the fermentation rooms. Currently, KAUKO does fermentation in big plastic buckets of average 100-200Litres. Fermentation time is about two (2) weeks, it is at this point that the two favorite brands are made; INGINGO and INKERA. For INKERA, sorghum is added, and INGINGO, ginger and Tea are added to cause the flavor.

Water Treatment: KAUKO uses treated (chlorine) piped water, but strictly goes through the electric UV system to ensure it is free of microbes and heavy metals that can be harmful for human consumption. Quality Standards: All KAUKO products must adhere to standards. Adhering to quality standards is deeply rooted in the qualified and experienced staff at the brewery. Through the Continuous

Professional Development (CPD) program, staff are kept up to speed with the brewing standards and technologies. A fully equipped quality lab is right opposite the two fermentation room; fully equipped with sampling and testing equipments duly certified by RBS and FDA.

After the two weeks of fermentation, beer is pumped to the bottle filling tanks, each carrying 120 liters. Currently, filling bottles with beers and covering them with covers are manually done.

In KAUKO expansion plans, this process shall certainly be replaced with machines. Fifteen (15) workers are used to fill and cover on average between 600-900 bottles a day.

But with a machine, with a few manpower, up to 5000 bottles can be filled in just 1 hour. With the expansion plans, KAUKO targets producing over 10,000Litres of beer a day.

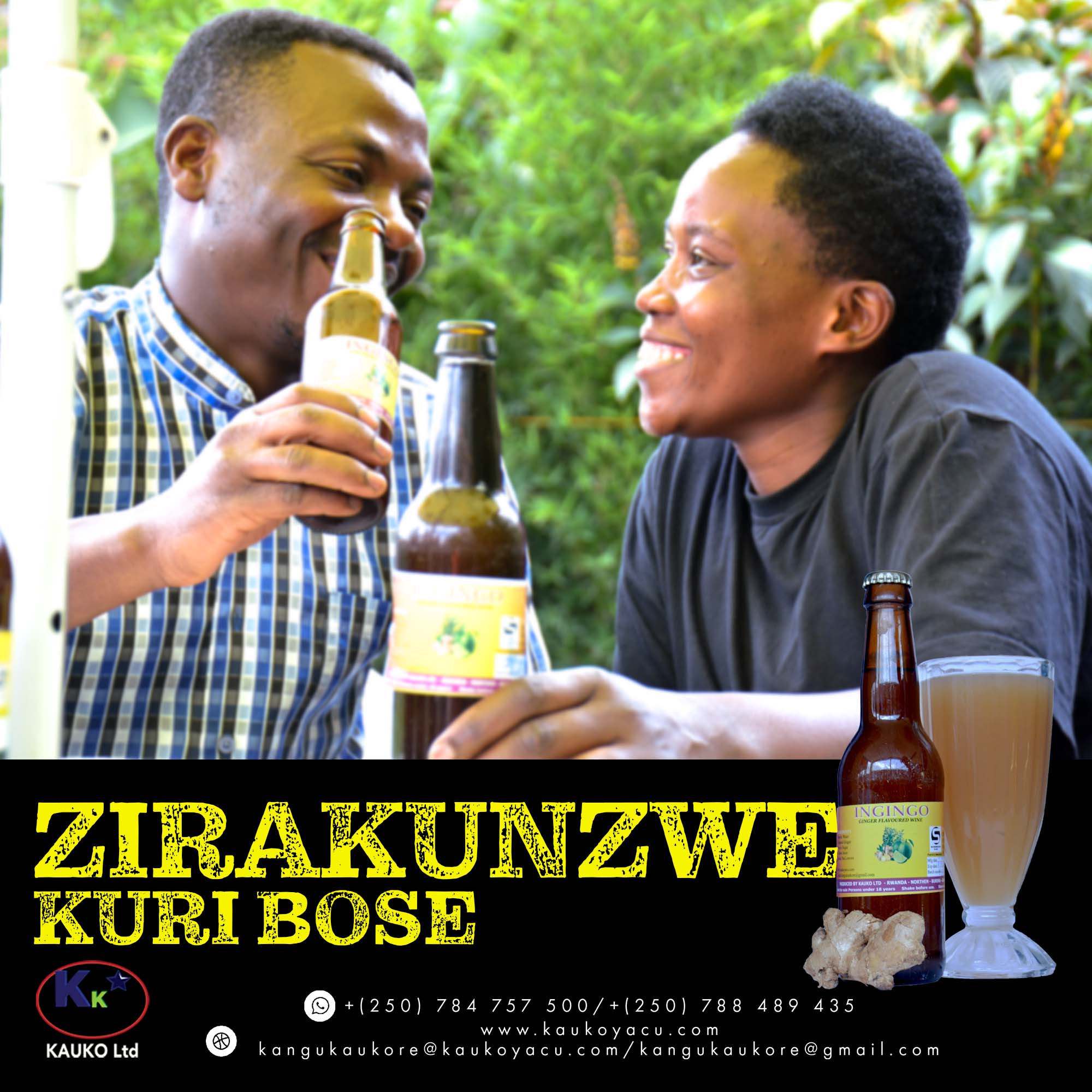

INGINGO and INKERA are labeled differently, indicating the ingredients, alcoholic content and quality and standard marks; including; RSB Quality Mark, FDA and Made in Rwanda. Those details are

displayed on the bottle to guide consumers. The FDA quality mark is scanned and incorporated on the label to give assurance to our consumers.

A standard KAUKO beer bottle carries 33ml, packed in a crate of 24 bottles. Brown Crates are for INKERA beers, whereas Green Crates are for INGINGO Beers. Each bottle is compliant with the international standards. Stockists can easily place their orders after payments on KAKUKO bank account or they can use MoMo.

KAUKO has fleet of trucks that deliver directly to Stockists’ place of business. KAUKO products are distributed through their depots across the country or stockists across the country.

In the KAUKO LTD 5 years marketing plan (2022-2027), plans are underway to start exporting to neighboring countries leveraging on compliance with quality and standard requirements and trade integration opportunities